Model No.: Magnet Electromagnetic Chuck

Description Crane Lifting Magnet Electromagnetic Chuck For Handling Steel Plates Lifting electromagnet is special equipment which utilizes the electric & magnetic physical quantity to lift attached materials and has become indispensable when to lift and transport ferromagnetism materials in lines of metallurgy, mine, machinery, shipbuilding and transportation etc and it can also be used as electromagnetic manipulator magnetic force centering bar length fixing and so on in some fields. As the attached materials are diverse, the electromagnet structure magnetic circuit and manufacturing process are also different. So there are many series of strong targeted products. Series MW5 Suitable for cast ingot, steel ball, iron, machine chip, for various kind of steel scraps, return scraps, cropping, baling scraps and etc in foundry factories and for iron powder in coal washery, during slag disposal process, it can remove large size of iron at initial step, outlet box has two chambers, an extra-thick fender and an anti-twist setting. There are three excitation options, rated voltage DC220V, strong excitation, over excitation. Features Advantages Crane Lifting Magnet Electromagnetic Chuck For Handling Steel Plates 1. Adopt totally sealing structure with good property of moisture- proofing, non-magnetic fender is made of rolled Mn plate which has good property of weldability magnetism- isolation, wear-resistant and shockproof. 2. Overseas technology has been introduced improved innovated as well as get optimum designed by computer to make our products reasonable structure, light self-weight strong attraction force and low energy consumption. 3. The energizing coils have been processed by special technology and thus its property of electrical and mechanical gets enhanced. Heat-resistant of insulating material reaches grade C and service life is long. 4. Rated duty cycle of normal electromagnet gets increased from 50% in the past to 60% thus working efficiency gets improved. 5. Over high temperature electromagnet adopts unique isolation from heat and radiation, the temperature of attached materials gets increased from 600ºC in the past to 700ºCwhich expands application range of electromagnet. 6. A full set of auxiliary unit such as control cubicle, cable reel etc can be provided as well. 7. Installation, operation and maintenance are convenient. Sketch

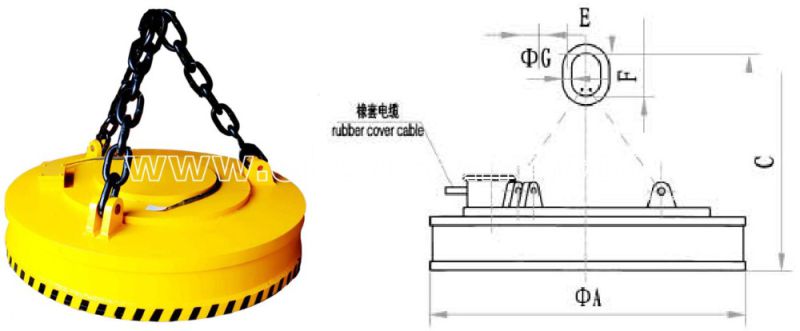

Description Crane Lifting Magnet Electromagnetic Chuck For Handling Steel Plates Lifting electromagnet is special equipment which utilizes the electric & magnetic physical quantity to lift attached materials and has become indispensable when to lift and transport ferromagnetism materials in lines of metallurgy, mine, machinery, shipbuilding and transportation etc and it can also be used as electromagnetic manipulator magnetic force centering bar length fixing and so on in some fields. As the attached materials are diverse, the electromagnet structure magnetic circuit and manufacturing process are also different. So there are many series of strong targeted products. Series MW5 Suitable for cast ingot, steel ball, iron, machine chip, for various kind of steel scraps, return scraps, cropping, baling scraps and etc in foundry factories and for iron powder in coal washery, during slag disposal process, it can remove large size of iron at initial step, outlet box has two chambers, an extra-thick fender and an anti-twist setting. There are three excitation options, rated voltage DC220V, strong excitation, over excitation. Features Advantages Crane Lifting Magnet Electromagnetic Chuck For Handling Steel Plates 1. Adopt totally sealing structure with good property of moisture- proofing, non-magnetic fender is made of rolled Mn plate which has good property of weldability magnetism- isolation, wear-resistant and shockproof. 2. Overseas technology has been introduced improved innovated as well as get optimum designed by computer to make our products reasonable structure, light self-weight strong attraction force and low energy consumption. 3. The energizing coils have been processed by special technology and thus its property of electrical and mechanical gets enhanced. Heat-resistant of insulating material reaches grade C and service life is long. 4. Rated duty cycle of normal electromagnet gets increased from 50% in the past to 60% thus working efficiency gets improved. 5. Over high temperature electromagnet adopts unique isolation from heat and radiation, the temperature of attached materials gets increased from 600ºC in the past to 700ºCwhich expands application range of electromagnet. 6. A full set of auxiliary unit such as control cubicle, cable reel etc can be provided as well. 7. Installation, operation and maintenance are convenient. Sketch  MW5

MW5 | Series MW5 normal temperature type | |||||||||||

| Main technical data (rated voltage DC-220V, duty cycle TD-60%) | |||||||||||

| Model | Cold state Power (KW) | Current A (cold/hot state) | Overall dimension(mm) | Weight(kg) | Lifting capacity(kg) (cold/hot state) | ||||||

| A | C | F | E | G | stell ball | casting ingot | chips | ||||

| MW5-50L/1 | 2.6 | 11.8/7.7 | 500 | 700 | 160 | 90 | 25 | 220 | 1200 | 220/130 | 80/65 |

| MW5-60L/1 | 3 | 13.6/8.9 | 600 | 750 | 160 | 90 | 25 | 340 | 2000 | 290/170 | 95/80 |

| MW5-70L/1 | 3.3 | 15/9.8 | 700 | 800 | 160 | 90 | 30 | 490 | 2500 | 380/200 | 120/100 |

| MW5-80L/1 | 4 | 18/12 | 800 | 800 | 160 | 90 | 30 | 620 | 3000 | 480/250 | 150/130 |

| MW5-90L/1 | 5.9 | 26.8/17.5 | 900 | 1090 | 200 | 125 | 40 | 800 | 4500 | 600/400 | 250/200 |

| MW5-110L/1 | 7.7 | 35/22.8 | 1100 | 1140 | 220 | 150 | 45 | 1350 | 6500 | 1000/800 | 450/400 |

| MW5-120L/1 | 10 | 45.5/29.5 | 1200 | 1100 | 220 | 150 | 45 | 1700 | 7500 | 1300/1000 | 600/500 |

| MW5-130L/1 | 12 | 54.5/35.5 | 1300 | 1240 | 250 | 175 | 50 | 2010 | 8500 | 1400/1100 | 700/600 |

| MW5-150L/1 | 15.6 | 70.9/46.1 | 1500 | 1250 | 350 | 210 | 60 | 2830 | 11000 | 1900/1500 | 1100/900 |

| MW5-165L/1 | 16.5 | 75/48.8 | 1650 | 1590 | 370 | 230 | 75 | 3200 | 12500 | 2300/1800 | 1300/1100 |

| MW5-180L/1 | 22.5 | 102.3/66.5 | 1800 | 1490 | 370 | 230 | 75 | 4230 | 14500 | 2750/2100 | 1600/1350 |

| MW5-210L/1 | 28.4 | 129/84 | 2100 | 1860 | 400 | 250 | 80 | 7000 | 21000 | 3500/2800 | 2200/1850 |

| MW5-240L/1 | 33.9 | 154/100 | 2400 | 2020 | 450 | 280 | 90 | 9000 | 26000 | 4800/3800 | 2850/2250 |

| MW5-260L/1 | 35.6 | 162/105 | 2600 | 2100 | 450 | 280 | 90 | 10100 | 30000 | 6100/4900 | 3600/3850 |

| MW5-280L/1 | 39 | 178/116 | 2800 | 2700 | 500 | 300 | 100 | 12450 | 34000 | 7100/5700 | 4450/3400 |

| MW5-300L/1 | 41.6 | 189/123 | 3000 | 2300 | 500 | 300 | 100 | 14890 | 39000 | 8350/6700 | 5250/4100 |

| Series MW5 high frequency type | |||||||||||

| Main technical data (rated voltage DC-220V, duty cycle TD-75%) | |||||||||||

| Model | Cold state Power (KW) | Current A (cold/hot state) | Overall dimension(mm) | Weight(kg) | Lifting capacity(kg) (cold/hot state) | ||||||

| A | C | F | E | G | stell ball | casting ingot | chips | ||||

| MW5-50L/1-75 | 2 | 9.1/6 | 500 | 700 | 160 | 90 | 25 | 253 | 1200 | 220/130 | 80/65 |

| MW5-60L/1-75 | 2.32 | 10.6/6.9 | 600 | 750 | 160 | 90 | 25 | 390 | 2000 | 290/170 | 95/80 |

| MW5-70L/1-75 | 2.55 | 11.6/7.6 | 700 | 800 | 160 | 90 | 30 | 550 | 2500 | 380/200 | 120/100 |

| MW5-80L/1-75 | 3.1 | 14.1/9.2 | 800 | 850 | 160 | 90 | 30 | 690 | 3000 | 480/250 | 150/130 |

| MW5-90L/1-75 | 4.6 | 21/13.6 | 900 | 1160 | 200 | 125 | 40 | 885 | 4500 | 600/400 | 250/200 |

| MW5-110L/1-75 | 6.1 | 27.7/18 | 1100 | 1270 | 220 | 150 | 45 | 1500 | 6500 | 1000/800 | 450/400 |

| MW5-120L/1-75 | 7.4 | 33.6/21.9 | 1200 | 1220 | 220 | 150 | 45 | 1850 | 7500 | 1300/1000 | 600/500 |

| MW5-130L/1-75 | 9 | 40.9/26.6 | 1300 | 1290 | 250 | 175 | 50 | 2280 | 8500 | 1400/1100 | 700/600 |

| MW5-150L/1-75 | 11.3 | 51.4/33.4 | 1500 | 1360 | 350 | 210 | 60 | 3180 | 11000 | 1900/1500 | 1100/900 |

| MW5-165L/1-75 | 12.2 | 55.5/36 | 1650 | 1670 | 370 | 230 | 75 | 3840 | 12500 | 2300/1800 | 1300/1100 |

| MW5-180L/1-75 | 16.3 | 74.1/48.2 | 1800 | 1800 | 370 | 230 | 75 | 4690 | 14500 | 2750/2100 | 1600/1350 |

| MW5-210L/1-75 | 21.7 | 98.6/64.1 | 2100 | 1900 | 400 | 250 | 80 | 7500 | 21000 | 3500/2800 | 2200/1850 |

| MW5-240L/1-75 | 25.9 | 117.7/76.5 | 2400 | 2100 | 450 | 280 | 90 | 9800 | 26000 | 4800/3800 | 2850/2250 |

| MW5-260L/1-75 | 27.5 | 125/83 | 2600 | 2150 | 450 | 280 | 90 | 11000 | 30000 | 6100/4900 | 3600/3850 |

| MW5-280L/1-75 | 30.5 | 139/90 | 2800 | 2250 | 500 | 300 | 100 | 13600 | 34000 | 7100/5700 | 4450/3400 |

| MW5-300L/1-75 | 32.5 | 148/96 | 3000 | 2350 | 500 | 300 | 100 | 16500 | 39000 | 8350/6700 | 5250/4100 |

| Series MW5 high temperature type | |||||||||||

| Main technical data (rated voltage DC-220V, duty cycle TD-60%) | |||||||||||

| Model | Cold state Power (KW) | Current A (cold/hot state) | Overall dimension(mm) | Weight(kg) | Lifting capacity(kg) (cold/hot state) | ||||||

| A | C | F | E | G | stell ball | casting ingot | chips | ||||

| MW5-50L/2 | 2 | 9.1/6 | 500 | 700 | 160 | 90 | 25 | 220 | 1200 | 220/130 | 80/65 |

| MW5-60L/2 | 2.3 | 10.5/6.8 | 600 | 750 | 160 | 90 | 25 | 395 | 2000 | 290/170 | 95/80 |

| MW5-70L/2 | 2.8 | 12.7/8.3 | 700 | 800 | 160 | 90 | 30 | 520 | 2500 | 380/200 | 120/100 |

| MW5-80L/2 | 3.54 | 16.1/10.5 | 800 | 850 | 160 | 90 | 30 | 650 | 3000 | 480/250 | 150/130 |

| MW5-90L/2 | 4.5 | 20.5/13.3 | 900 | 1160 | 200 | 125 | 40 | 900 | 4500 | 600/400 | 250/200 |

| MW5-110L/2 | 6 | 27.3/17.7 | 1100 | 1270 | 220 | 150 | 45 | 1500 | 6500 | 1000/800 | 450/400 |

| MW5-120L/2 | 7.4 | 33.6/21.9 | 1200 | 1220 | 220 | 150 | 45 | 1800 | 7500 | 1300/1000 | 600/500 |

| MW5-130L/2 | 8.9 | 40.5/26.3 | 1300 | 1290 | 250 | 175 | 50 | 2100 | 8500 | 1400/1100 | 700/600 |

| MW5-150L/2 | 11.3 | 51.4/33.4 | 1500 | 1360 | 350 | 210 | 60 | 3200 | 11000 | 1900/1500 | 1100/900 |

| MW5-165L/2 | 13.3 | 60.5/39.3 | 1650 | 1670 | 370 | 230 | 75 | 3500 | 12500 | 2300/1800 | 1300/1100 |

| MW5-180L/2 | 20.9 | 95/61.8 | 1800 | 1800 | 370 | 230 | 75 | 4500 | 14500 | 2750/2100 | 1600/1350 |

| MW5-210L/2 | 22.9 | 104.1/67.7 | 2100 | 1900 | 400 | 250 | 80 | 7500 | 21000 | 3500/2800 | 2200/1850 |

| MW5-240L/2 | 26 | 118.2/76.8 | 2400 | 2100 | 450 | 280 | 90 | 9800 | 26000 | 4800/3800 | 2850/2250 |

| MW5-260L/2 | 27.5 | 125/83 | 2600 | 2150 | 450 | 280 | 90 | 11000 | 30000 | 6100/4900 | 3600/3850 |

| MW5-280L/2 | 30 | 136/89 | 2800 | 2250 | 500 | 300 | 100 | 13700 | 34000 | 7100/5700 | 4450/3400 |

| MW5-300L/2 | 32 | 146/95 | 3000 | 2350 | 500 | 300 | 100 | 16480 | 39000 | 8350/6700 | 5250/4100 |

| Series MW5 strong magnet type | |||||||||||

| Main technical data (rated voltage DC-220V) | |||||||||||

| Model | Cold state Power (KW) | Current A (cold/hot state) | Overall dimension(mm) | Weight(kg) | Lifting capacity(kg) (cold/hot state) | ||||||

| A | C | F | E | G | stell ball | casting ingot | chips | ||||

| MW5-165L/1-QC | 17.6 | 80/52 | 1650 | 1730 | 370 | 230 | 75 | 4250 | 13500 | 2650/2100 | 1500/1300 |

| MW5-180L/1-QC | 22.8 | 104/67.4 | 1800 | 1870 | 370 | 230 | 75 | 5600 | 16000 | 3100/2400 | 1900/1600 |

| MW5-210L/1-QC | 32.6 | 148/96 | 2100 | 1980 | 400 | 250 | 80 | 8300 | 23100 | 4000/3200 | 2600/2180 |

| MW5-240L/1-QC | 43 | 195/127 | 2400 | 2200 | 450 | 280 | 90 | 10800 | 28600 | 5500/4400 | 3360/2650 |

CONTACT US |

Wayne He |

|

Mobile: +86 13770780269 |

Telephone: +86 0371 86253526 |

Co. Website: http://www.shenqicrane.com/ |

For more information and details about our products, including design of the crane, safety features of each kind of crane, application of the machine, technical parameters of the crane, production process, after-sale service, main part of the crane,package for the crane, loading pictures of cranes and all other information about our products, please kindly contact with MR.Wayne , MR.Wayne will give you a support as much as possible. |

Product Categories : Lifting Device/Under Hook